Back to Originals. Prior to about 1890, lime putty mortar was used for the construction of the Alsatian and other stone structures. It was one of very few choices, available and well known by stone masons. Without proper maintenance, sooner or later erosion, settling, and use causes stone structures to fail and require repairs.

Advances in technology are often overused and misused. One great example is the use of Portland cement to repair stone homes built prior to 1890. Portland cement came along in the 1890’s and was advanced and perfected to bond aggregate into a solid foundation or sidewalk or highway overpass. But in this very relevant Alsatian restoration, the original is better than the new. Ask any skilled architect or stone mason. Portland cement is very good for other purposes, but it has characteristics that makes it a bad repair and patching material for a limestone block home. It expands at a different rate than the native limestone in the case of temperature and humidity fluxuations. It is also a glaringly grey, ugly filler that does not match the tan stones whatsoever. It looks out of place and it is a bad actor, accelerating further erosion and damage.

Replacing the mortar in between the stones is a process called repointing. First all of the exterior hardware is removed, electrical wiring, gate attachment points, rods, well intenioned steel plates, pipes, re-bar and more. Then all of the mortar is removed from one side of the wall between the stones-halfway through-whether it is Portland or the original lime putty mortar.

New mortar is made and with proper care and attention, the addition of limestone from the same sources as the stone are used as the aggregate. This gives the mortar a similar color to the stones, but also grows and shrinks along with the stone more harmoniously. The mixture is troweled by hand into the crevices to rebond the loose stones and to further stabilize all others.

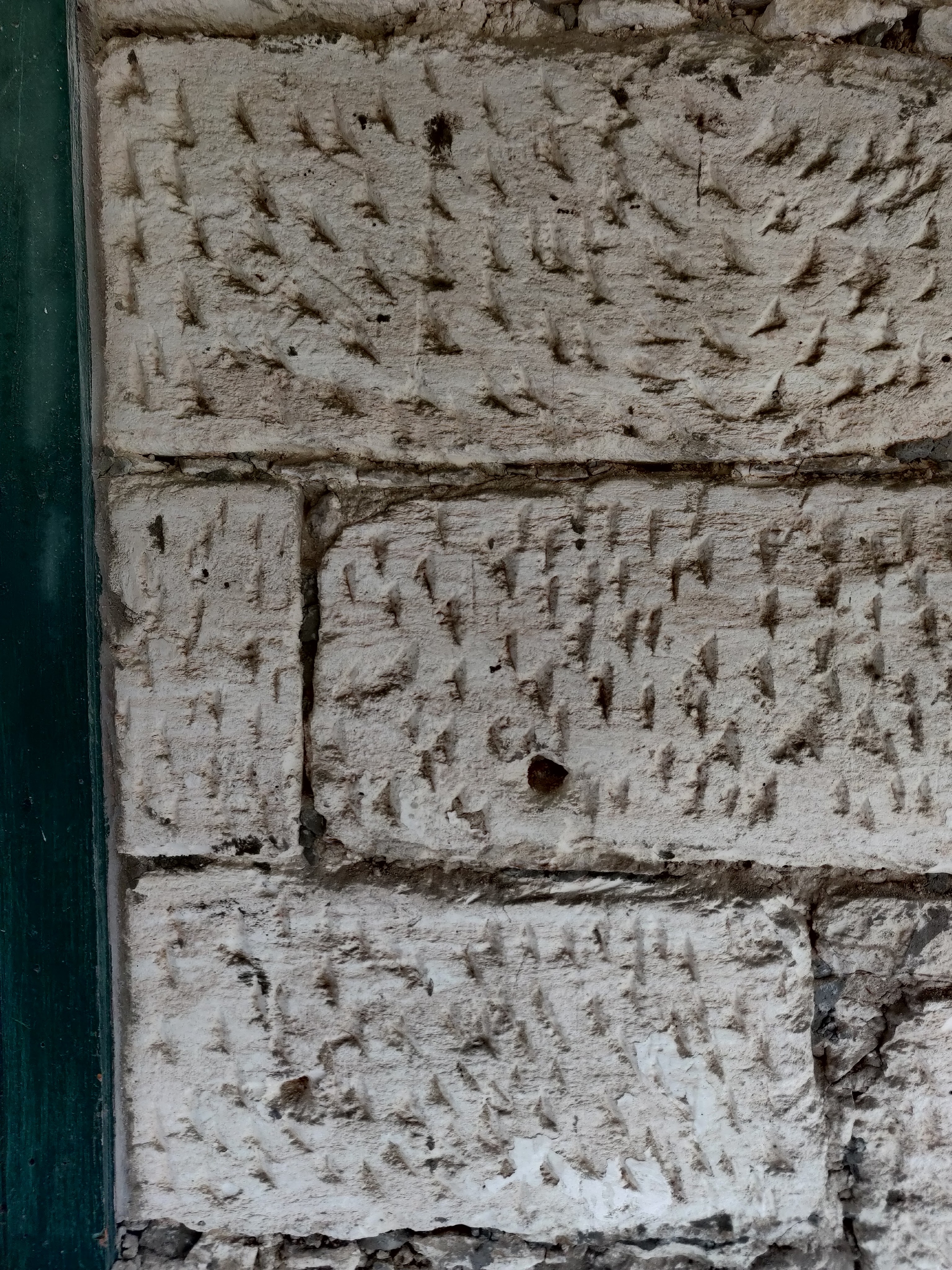

Most of the larger stone blocks at the Rohrbach home have chisel marks on the stone face. This process was done by the original stone mason to increase the purchase or bonding power of the planar wall surface to accept a lime-plaster scratch coat of lime whitewash.

Images above from the 2021-2022 ongoing renovation. There are different chisel marks in each room and wall indicating different masons or time periods for construction. The Rohrbach home was built one room at a time, probably over several years.

Lime Mortar Chemistry

Calcite fired in kiln to produce quicklime.

CaCO₃ + HEAT → Ca0 + CO₂

Quicklime slaked to make hydrated lime.

CaO + H₂O → Ca(OH)₂

Hydrated lime (dissoved in mortar) exposed to air, reforms into calcite.

Ca(OH)₂ + CO₂ → CaCO₃ + H₂O